When we moved late last yr, we also took our old spa pool.

I knew not to strap it down too tight on the trailer, but as happens, someone comes along 'checks' tie downs and knicks them up a bit more.

This slightly distorted one end of the pool...which resulted in 5 of a set of 5 jets leak between the jet and the outer pool wall.

I figured out how to take the jets out.. bit of a mission because of how they where installed at the factory.

Anyway, I was looking at them and the factory install just didnt seem right to me... so contacted the manufacturers and sure enough, how installed is how they still do them.

In saying that, they did comment that the only issue they have with pools over the decades is leaking between the jet and pool wall...

So Im thinking hmmm.. still recon its wrong.

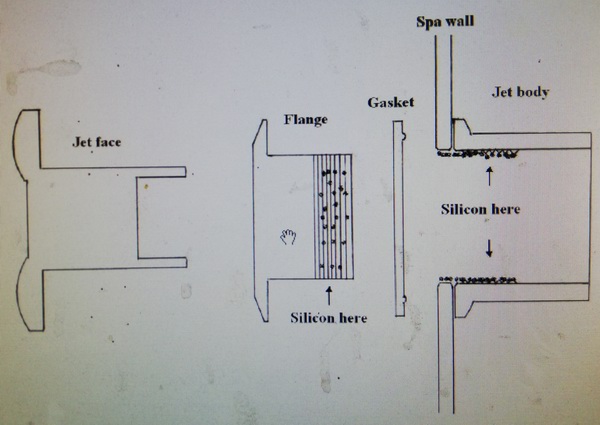

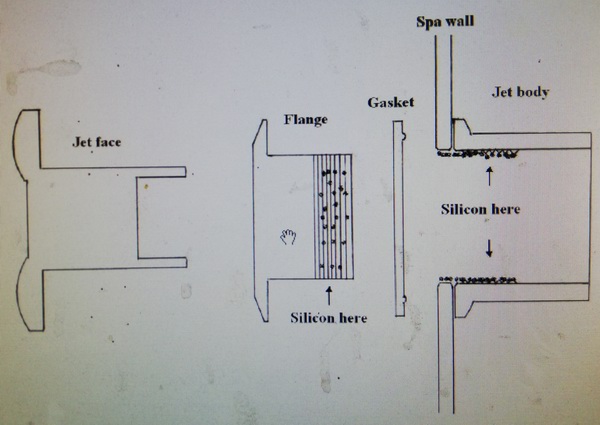

Now here is the pic they sent...look at it..

note the little dots..

they silicone.. which is not comparable with the jet plastic or the plastic of the pool wall...silcone as a gasket between the outter part of the wall and jet and the threads that water may seep up to get to the jet/ outter wall seal.

And put the rubberises plastic seal in the inside of the pool wall where there is no need to seal at all !!!

Now im no expert.. they are...am I missing something here?

I recon all that is needed is put the gasket on the outside of the wall...forget the sealant/ silcone.

Any sealant/ gasket on the inside...well it cant leak into its self on the inside surface right?

Have they been installing wrong for over the last 3 decades?